The construction industry demands reliability when projects are on tight deadlines and safety is paramount. Whether you’re working on a high-rise development in downtown Salt Lake City or managing infrastructure projects across Utah’s diverse terrain, having the right equipment can make or break your timeline and budget.

Modern worksites present unique challenges that require versatile, powerful machinery capable of adapting to changing conditions.

From extreme weather fluctuations to varying ground conditions, construction teams need equipment that performs consistently regardless of the environment. The key lies in selecting machinery designed with durability and flexibility at its core.

Understanding Worksite Demands

Every construction project faces its own set of obstacles. Urban developments deal with tight spaces and noise restrictions, while rural projects may encounter unstable ground conditions or limited access routes. Mining operations require equipment that can withstand harsh environments and continuous operation cycles.

Weather conditions add another layer of complexity. Equipment must function reliably through scorching summer heat, freezing winter temperatures, and everything in between. This is particularly important in regions like Utah, where elevation changes and seasonal variations create demanding operating conditions.

The most successful projects rely on machinery that can handle multiple tasks efficiently. Multi-purpose equipment reduces the need for numerous specialized machines, streamlining logistics and cutting costs.

This approach proves especially valuable when dealing with remote locations where transporting multiple pieces of equipment becomes challenging and expensive.

Key Features of Reliable Construction Equipment

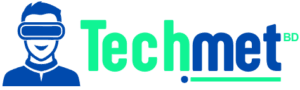

Robust Build Quality

Premium equipment starts with superior engineering and materials. Heavy-duty steel frames, reinforced joints, and quality components ensure longevity under extreme stress. Manufacturers who prioritize build quality often provide longer warranties and better resale values, making them smart long-term investments.

Advanced Hydraulic Systems

Modern hydraulic technology delivers precise control and consistent power output. These systems maintain performance across temperature ranges and provide operators with the responsiveness needed for delicate tasks or heavy lifting operations.

Enhanced Safety Features

Today’s equipment includes advanced safety systems like load monitoring, stability controls, and operator protection systems. These features protect both personnel and project investments while meeting increasingly strict safety regulations.

Versatile Attachments

Equipment that accommodates various attachments maximizes utility across different project phases. This flexibility allows contractors to adapt quickly to changing project requirements without sourcing additional machinery.

Selecting the Right Equipment for Your Project

Choosing appropriate equipment requires careful assessment of project requirements, site conditions, and operational constraints. Consider factors like lifting capacity, reach requirements, mobility needs, and terrain challenges when making decisions.

For projects requiring exceptional reach and lifting capability, specialized equipment like all terrain crane rental in Utah offers solutions that combine mobility with power. These cranes can navigate challenging terrain while providing the capacity needed for major construction tasks.

Capacity Planning

Always account for future project phases when selecting equipment. Choosing machinery with slightly higher capacity than current needs provides flexibility for scope changes and ensures you’re not limited by equipment constraints as projects evolve.

Site Accessibility

Evaluate access routes, ground conditions, and space constraints before equipment arrives. This planning prevents costly delays and ensures smooth operation throughout the project timeline.

Operator Training

Even the best equipment performs poorly without skilled operators. Invest in proper training to maximize equipment potential and maintain safety standards. Many equipment providers offer training programs as part of their service packages.

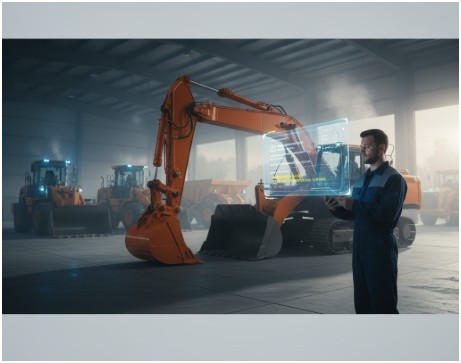

Maintenance and Performance Optimization

Regular maintenance schedules keep equipment operating at peak performance while preventing costly breakdowns. Establish preventive maintenance routines that include daily inspections, fluid checks, and component monitoring.

Modern equipment often includes telematics systems that provide real-time performance data and maintenance alerts. These systems help optimize operations while extending equipment life through proactive care.

Documentation and Record Keeping

Maintain detailed records of equipment usage, maintenance, and performance issues. This information proves valuable for warranty claims, resale negotiations, and future equipment selection decisions.

Making Smart Equipment Decisions

The most successful construction companies view equipment selection as a strategic advantage rather than a necessary expense. They understand that reliable machinery reduces project risks, improves timeline predictability, and enhances profitability.

Consider partnering with equipment providers who offer comprehensive support services, including maintenance, training, and technical assistance. These relationships often prove more valuable than simply securing the lowest rental rates.

When your next project demands equipment that can handle any challenge, remember that quality and reliability should guide your decisions.

The right machinery doesn’t just complete tasks—it provides the foundation for project success, safety, and profitability. Invest in equipment built to exceed expectations, and watch your projects run smoother than ever before.